A manual transmission parts diagram illustrates the components, such as the input shaft, countershaft, and synchronizers, showcasing how they work together to enable smooth gear transitions and efficient power delivery.

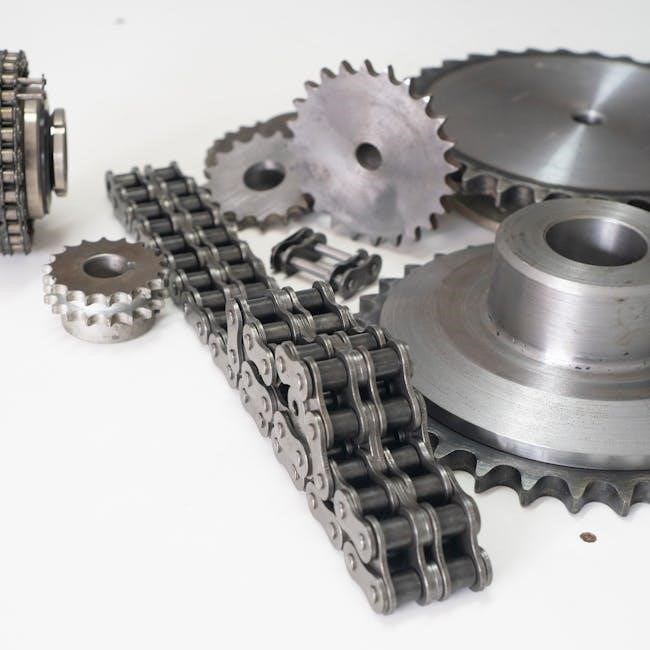

Overview of Manual Transmission Components

A manual transmission consists of several critical components that work together to enable gear changes. The input shaft connects to the engine, transferring power into the transmission. The output shaft delivers this power to the drivetrain. The countershaft supports the gears, while synchronizers and dog clutches facilitate smooth gear engagement. Additional parts like the gear selector and shift fork are essential for manual operation. Understanding these components and their interactions is crucial for diagnosing issues and performing repairs. A parts diagram provides a visual guide, helping to identify each element and its role in the system. This overview lays the foundation for deeper exploration of the transmission’s mechanics and maintenance.

Importance of Understanding the Diagram

Understanding a manual transmission parts diagram is essential for effective troubleshooting and maintenance. It provides a clear visual representation of each component, allowing users to identify parts quickly. This knowledge helps in diagnosing issues accurately, such as worn gears or faulty synchronizers. By familiarizing oneself with the diagram, mechanics and enthusiasts can perform repairs more efficiently, reducing downtime and costs. Additionally, it aids in ordering the correct replacement parts and ensures proper reassembly after maintenance. A comprehensive understanding of the diagram is vital for anyone seeking to master manual transmission mechanics and keep their vehicle in optimal condition.

Key Components of a Manual Transmission

The core components include the input shaft, output shaft, countershaft, gears, synchronizers, and dog clutches, each playing a vital role in transmitting power and enabling smooth gear shifts.

Input Shaft and Output Shaft

The input shaft connects directly to the engine, receiving power through the clutch. It rotates the gears on the countershaft, which meshes with the output shaft. The output shaft transfers power to the driveshaft, propelling the vehicle. Both shafts are essential for transmitting torque efficiently, ensuring smooth operation under various driving conditions. Proper alignment and lubrication are crucial to prevent wear and tear, maintaining optimal performance and longevity of the transmission system.

Countershaft and Gears

The countershaft, also known as the layshaft, is a central component in the manual transmission system. It rotates independently and is connected to the input shaft, transferring power to the gears. The countershaft features multiple gears of varying sizes, which mesh with gears on the input and output shafts to provide different gear ratios. These gears are typically in constant mesh, allowing for smooth transitions between speeds. The countershaft is mounted on bearings within the transmission case, ensuring stability and durability. Proper lubrication of the countershaft and gears is essential for maintaining efficient operation and preventing wear over time.

Synchronizers and Dog Clutches

Synchronizers and dog clutches are critical components in a manual transmission, ensuring smooth gear engagement. Synchronizers are responsible for matching the speed of the gear to the shaft, preventing grinding during shifts. They use frictional force to synchronize the rotational speed of the gear and shaft. Dog clutches, on the other hand, are toothed components that engage with gears to lock them to the shaft. When the driver selects a gear, the dog clutch moves into position, securing the gear in place. This precise interaction between synchronizers and dog clutches allows for seamless gear transitions, making manual shifting efficient and driver-friendly.

How to Read a Manual Transmission Parts Diagram

Understanding a manual transmission parts diagram involves identifying components like gears, shafts, and synchronizers, and recognizing how they connect to facilitate gear shifts and power transmission.

Identifying Major Parts and Their Functions

The manual transmission parts diagram highlights key components such as the input shaft, which connects to the engine, and the output shaft, linking to the driveshaft. The countershaft holds gears in constant mesh, while synchronizers ensure smooth gear engagement. Dog clutches lock gears to the output shaft, and shift forks move the synchronizers. Each part’s role is essential for transmitting power and enabling precise gear shifts. By analyzing the diagram, one can trace how power flows through these components, from the engine to the wheels, ensuring efficient and controlled movement.

Understanding Gear Ratios and Shaft Connections

Gear ratios in a manual transmission are determined by the relationship between the sizes of meshing gears on the input and output shafts. A smaller gear on the input shaft paired with a larger gear on the output shaft results in a lower gear ratio, providing more torque for acceleration. Conversely, a larger input gear with a smaller output gear offers a higher gear ratio, suitable for higher speeds. The countershaft, with its fixed gears, plays a crucial role in these ratios by meshing with gears on both the input and output shafts. Shaft connections are essential for transferring power smoothly, with the input shaft linked to the engine and the output shaft to the driveshaft. These connections ensure that the selected gear ratio effectively transmits power, optimizing vehicle performance across various driving conditions.

Common Repairs and Maintenance

Common manual transmission repairs involve replacing worn-out components like synchronizers, bearings, and seals. Regular lubrication and adjustment of gears and clutches ensure smooth operation and prevent premature wear.

Replacing Worn-Out Parts

Replacing worn-out parts in a manual transmission is essential for maintaining smooth operation. Components like synchronizers, dog clutches, and bearings often require replacement due to wear. Using a parts diagram helps identify these components accurately. The process typically involves dismantling the gearbox, inspecting each part, and replacing damaged or worn items. Proper tools and lubrication are crucial during reassembly. Delaying replacements can lead to further damage, such as gear misalignment or complete system failure. Always consult a professional if unsure, as improper installation can compromise safety and performance. Regular inspection and timely replacements ensure optimal functionality and extend the transmission’s lifespan.

Adjusting and Lubricating Components

Adjusting and lubricating manual transmission components are critical for optimal performance. Parts like synchronizers, gears, and bearings require precise adjustment to ensure smooth shifting and minimize wear. Using a parts diagram, technicians can identify components needing adjustment, such as shift forks or gear selectors. Proper lubrication involves applying high-quality gear oil to moving parts, ensuring reduced friction and extended lifespan. Regular maintenance helps prevent overheating and premature wear. Always follow manufacturer guidelines for lubricant types and application amounts. Neglecting these steps can lead to noisy operation or gear slippage, emphasizing the importance of routine checks and timely adjustments to maintain transmission health.

Troubleshooting Tips

Common manual transmission issues include difficulty shifting gears or unusual noises. Referencing a parts diagram helps identify faulty components, such as worn synchronizers or damaged gears, for repair.

Diagnosing Common Issues

Common issues in manual transmissions often manifest as difficulty shifting gears, unusual noises, or fluid leaks. By referencing a parts diagram, technicians can trace symptoms to specific components like worn synchronizers or damaged gears. For instance, grinding noises during shifting may indicate faulty dog clutches or improperly aligned gear teeth. Leaks could point to a damaged input or output shaft seal. Using the diagram, one can visually locate these parts and assess their condition. Regular lubrication checks and inspecting gear engagement patterns are also crucial for early detection of potential problems. This systematic approach ensures accurate diagnoses and effective repairs, minimizing downtime and extending transmission lifespan.

Using the Diagram for Repair Guidance

A manual transmission parts diagram serves as a vital tool during repairs, providing a visual guide to locate and identify components. Technicians can use it to trace connections between parts like the input shaft, countershaft, and gears. By cross-referencing symptoms with the diagram, they can pinpoint issues such as worn synchronizers or misaligned gear teeth. The diagram also aids in understanding how components interact, ensuring proper reassembly after disassembly. Additionally, it helps in selecting the correct replacement parts, reducing errors and saving time. Regular use of the diagram enhances repair accuracy and efficiency, making it an indispensable resource for both professionals and DIY enthusiasts.

A manual transmission parts diagram is essential for understanding and maintaining vehicle gear systems, ensuring efficiency and longevity through accurate repairs and informed maintenance practices.

Key Takeaways

A manual transmission parts diagram is a vital tool for understanding and servicing gear systems. It highlights components like the input shaft, output shaft, and synchronizers, explaining their roles in power delivery. By studying the diagram, mechanics can identify worn parts, diagnose issues, and perform precise repairs. Regular maintenance, such as lubrication and adjustment, extends transmission life. Troubleshooting common problems, like gear slippage, becomes easier with a clear visual guide. Whether for repair or learning, a detailed diagram ensures efficiency and accuracy, making it indispensable for both professionals and enthusiasts working with manual transmissions.

Resources for Further Learning

For deeper understanding, explore detailed service manuals, exploded diagrams, and technical guides available online. Websites like Eurospares offer diagrams for specific models, such as the Porsche 997-1. Repair manuals and PDF guides provide comprehensive insights into transmission mechanics. Online forums and communities share hands-on experiences and tips from experienced mechanics. Additionally, manufacturer-specific resources, like those for Isuzu or Revtech transmissions, offer precise instructions. These tools are invaluable for DIY enthusiasts and professionals alike, ensuring accurate repairs and a thorough grasp of manual transmission systems. Leveraging these resources enhances both practical skills and theoretical knowledge.