Fagor Pressure Cooker Manual: A Comprehensive Guide

This manual provides detailed instructions for safe and effective operation of your Fagor pressure cooker, covering setup, use, and maintenance.

Fagor America offers resources, while online forums discuss user experiences and troubleshooting. Initial setup requires removing all packaging.

Fagor, a renowned name in kitchen appliances, offers a diverse range of pressure cookers designed to simplify and expedite your cooking process; These cookers, including the Duo, Premium, and Rapida models, utilize pressure to significantly reduce cooking times while preserving essential nutrients.

Understanding your Fagor pressure cooker begins with familiarizing yourself with its components and operational principles. This guide serves as a comprehensive resource, ensuring you can safely and efficiently harness the benefits of pressure cooking. Proper usage, guided by this manual, unlocks a world of culinary possibilities.

Understanding the Importance of the Manual

This Fagor pressure cooker manual is not merely a set of instructions; it’s your key to safe, efficient, and enjoyable cooking. Ignoring the guidelines can lead to improper operation, potential hazards, and diminished performance.

Detailed within are crucial safety precautions, component identification, and step-by-step operating procedures. User feedback highlights dissatisfaction with inadequate instructions from the manufacturer, emphasizing the need for this comprehensive guide. Familiarizing yourself with this manual ensures optimal results and longevity of your appliance.

Safety First: Essential Precautions

Prioritize safety by thoroughly reading all instructions before operation. Proper use prevents accidents and ensures optimal performance of your Fagor pressure cooker.

Reading the Safety Instructions

Before first use, carefully review the entire safety section of this manual. Understanding these precautions is crucial for preventing potential hazards associated with pressure cooking. Pay close attention to warnings regarding proper lid sealing, pressure release methods, and avoiding overfilling the cooker.

Fagor emphasizes the importance of familiarizing yourself with the pressure regulator and its functions. Ignoring safety guidelines can lead to burns, scalding, or damage to the appliance. Always operate the cooker on a stable, heat-resistant surface and keep it away from flammable materials.

Initial Setup and Inspection

Upon unboxing your Fagor pressure cooker, thoroughly remove all packing materials and literature. Inspect the unit for any visible damage, including dents, cracks, or loose parts. Verify that the removable cooking pot, lid, sealing ring, and pressure regulator are all present and in good condition.

Ensure the sealing ring is properly seated within the lid’s rim. Fagor recommends a gentle wash of the pot and lid with warm, soapy water before initial use. Confirm the locking mechanisms engage smoothly and securely.

Understanding Pressure Release Mechanisms

Fagor pressure cookers utilize several methods for safely releasing internal pressure. Natural Pressure Release allows the cooker to cool down gradually on its own, ideal for soups and delicate foods. Quick Pressure Release vents steam rapidly, shortening the process but potentially causing splattering.

Controlled Pressure Release offers a middle ground, allowing you to manually regulate steam release. Understanding these mechanisms is crucial for safe operation and optimal cooking results.

Components and Parts Identification

Fagor cookers feature a removable pot, secure lid with a sealing ring, a pressure regulator/valve, and robust handles with locking mechanisms for safety.

Removable Cooking Pot

The removable cooking pot is a central component, designed for easy filling, emptying, and cleaning. Constructed from durable materials, it withstands high pressure and temperature during cooking. Before first use, ensure the pot is free from any packaging or residue.

Carefully lift the pot out to wash it separately, avoiding abrasive cleaners that could damage the surface. This pot’s design facilitates even heat distribution, crucial for consistent cooking results. Always inspect for any dents or damage before each use.

Lid and Sealing Ring

The Fagor pressure cooker lid is engineered for a secure, airtight seal, essential for building and maintaining pressure. Inspect the sealing ring before each use for cracks, dryness, or deformation – replace if necessary. Proper alignment of the lid is crucial; ensure it clicks firmly into place.

Cleaning the lid and ring after each use prevents food buildup and maintains optimal performance. Avoid harsh chemicals that could degrade the sealing ring’s integrity. A properly sealed lid is vital for safe operation.

Pressure Regulator/Valve

The pressure regulator, or valve, is a critical safety component controlling internal pressure. Fagor cookers utilize different valve types; familiarize yourself with your model’s specific mechanism. Regularly inspect the valve for blockages or damage, ensuring it moves freely.

Understanding the valve’s settings – low, medium, high – allows for precise cooking control. A malfunctioning valve can compromise safety, so address any issues immediately. Never attempt to force or modify the pressure regulator.

Handles and Locking Mechanisms

Fagor pressure cookers feature robust handles designed for safe lifting and maneuvering, even when full. The locking mechanism is paramount; it confirms a secure seal before pressure builds. Always verify the lid is correctly locked before initiating cooking.

Never force the lid; ensure proper alignment. Inspect handles for cracks or damage before each use. A faulty locking mechanism prevents pressure buildup and poses a safety risk; discontinue use if compromised.

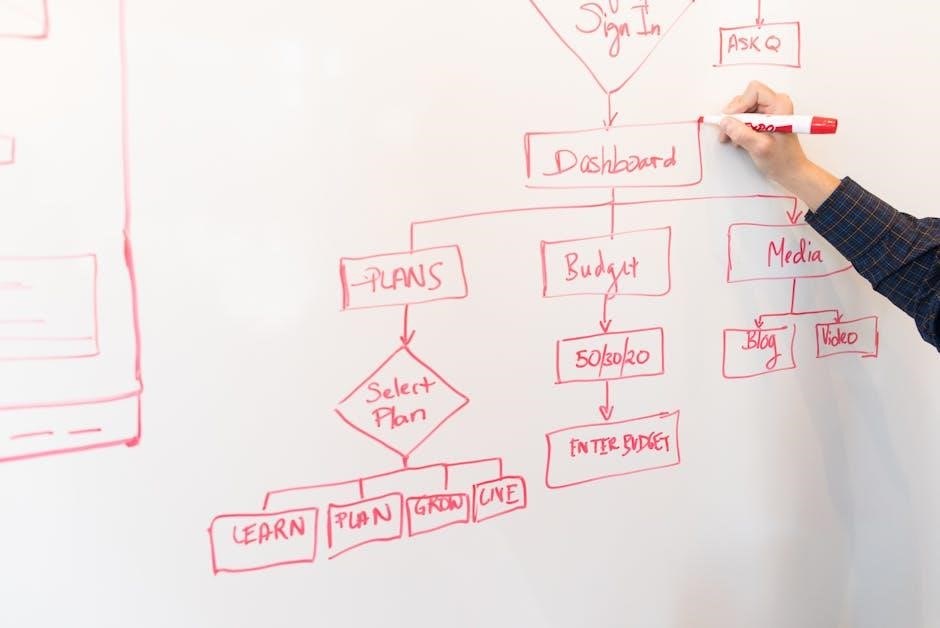

Operating Instructions: Step-by-Step

Begin by preparing the cooker, adding food and liquid, and securely locking the lid. Select the appropriate pressure level and cooking time for optimal results.

Preparing the Cooker for Use

Before the first use, carefully remove all packaging materials, including any literature found inside and around the Fagor pressure cooker. Lift out the removable cooking pot and ensure all protective pieces are removed. Inspect the sealing ring and ensure it is properly seated within the lid; this is crucial for building pressure. Verify the pressure regulator/valve is clean and unobstructed for safe operation. Familiarize yourself with the locking mechanisms to ensure a secure seal during cooking, preventing accidental openings.

Adding Food and Liquid

Always add liquid to the removable cooking pot before adding food; this prevents scorching. The minimum liquid requirement varies by recipe, but ensure sufficient liquid covers the food partially. Do not overfill the cooker – typically, never exceed two-thirds full for foods that expand during cooking, like beans or grains. Avoid filling beyond the maximum fill line indicated inside the pot. For optimal results, cut food into uniform sizes for even cooking.

Securing the Lid

Proper lid alignment is crucial for safe pressure cooking. Ensure the sealing ring is correctly positioned within the lid groove before attempting to close it. Align the lid with the cooker body, typically indicated by arrows or markings. Rotate the lid until it locks securely into place; a clicking sound confirms proper engagement. Never force the lid – if resistance is met, re-align and try again. Verify the locking indicators are fully engaged before pressurizing.

Selecting Pressure Levels

Fagor pressure cookers often feature multiple pressure settings, typically indicated by markings or a rotating dial. Lower settings are ideal for delicate foods like vegetables and fish, preserving texture and nutrients. Higher settings accelerate cooking times for tougher cuts of meat and beans. Consult recipes for recommended pressure levels. Always ensure the pressure regulator is correctly positioned for the chosen setting. Incorrect selection can impact cooking results and safety.

Cooking Time and Adjustments

Cooking times vary based on food type, quantity, and selected pressure level. Refer to recipes as a starting point, but adjustments may be needed. Altitude significantly impacts cooking times; higher altitudes require longer durations. Monitor the cooker and adjust time accordingly. Overcooking can lead to mushy textures, while undercooking poses a safety risk. Experience will help you refine your timing for optimal results. Always prioritize food safety.

Pressure Release Methods

Fagor cookers offer natural, quick, and controlled release options. Natural release is safest, while quick release is faster but requires caution. Controlled release offers a balance.

Natural Pressure Release

Natural pressure release involves allowing the cooker to cool down and the pressure to dissipate on its own, without any intervention. This is generally considered the safest method, particularly for foods that foam or splatter easily, like beans or grains.

Simply turn off the heat and allow the cooker to sit undisturbed. The time it takes for the pressure to release will vary depending on the amount of food and liquid inside. Avoid attempting to open the lid until the pressure indicator has fully dropped, ensuring complete safety.

This method preserves more nutrients and results in more tender food, making it ideal for tougher cuts of meat or delicate dishes.

Quick Pressure Release

Quick pressure release rapidly reduces pressure by activating the pressure release valve. This method is faster but requires caution, as hot steam will be forcefully expelled. It’s best suited for foods that don’t foam excessively, like vegetables.

Carefully follow the manual’s instructions for your specific Fagor model to locate and operate the valve. Always direct the steam away from your face and hands. Be aware that quick release can sometimes cause liquids to splatter.

Ensure the pressure indicator has dropped completely before attempting to open the lid.

Controlled Pressure Release

Controlled pressure release offers a middle ground between natural and quick release, minimizing splatter and preventing food from overcooking. This involves partially opening the pressure release valve, allowing steam to escape gradually.

The Fagor manual will detail the specific method for your model, often involving a slight turn of the valve. Monitor the pressure indicator closely during this process. It’s ideal for soups, stews, and dishes with a higher liquid content.

Exercise caution as steam will still be hot.

Cleaning and Maintenance

Regular cleaning ensures longevity and hygiene. Disassemble components after each use, wash thoroughly, and store properly. Fagor recommends hand washing for optimal care.

Disassembling the Cooker

Before cleaning, ensure the cooker is completely cool and pressure has been released. Carefully remove the removable cooking pot from the main housing. Detach the lid by unlocking the handles; it’s crucial to understand the locking mechanism.

Next, gently remove the sealing ring from the lid – inspect it for cracks or damage. The pressure regulator/valve can also be detached for separate cleaning. Always refer to the manual’s diagrams for precise component locations and removal procedures.

Washing the Components

After disassembly, wash the removable cooking pot, lid, and pressure regulator with warm, soapy water. Avoid abrasive cleaners that could damage the surfaces. The sealing ring requires gentle cleaning; inspect it regularly for wear and tear.

Ensure all components are thoroughly rinsed and dried before reassembly. Do not wash the cooker housing directly with water; wipe it clean with a damp cloth. Proper cleaning maintains hygiene and extends the cooker’s lifespan.

Storing the Pressure Cooker

Before storing, ensure the Fagor pressure cooker is completely cool and dry. Disassemble the components and store them separately to prevent damage or odor retention. Keep the sealing ring loose, not compressed, to maintain its elasticity.

Store the cooker in a clean, dry place, away from direct sunlight and extreme temperatures. Avoid stacking heavy items on top of it. Proper storage ensures longevity and readiness for your next culinary adventure.

Troubleshooting Common Issues

Common problems include sealing issues, regulator malfunctions, and food burning; Refer to this section for solutions and ensure safe, optimal cooker performance.

Lid Won’t Seal

If the lid fails to seal, first inspect the sealing ring for cracks, damage, or improper placement. Ensure it’s correctly positioned within the lid’s groove. Verify the rim of the cooking pot is clean and free from debris, as any particles can obstruct a tight seal.

Also, confirm the lid is properly aligned and locked into place; a misaligned lid won’t build pressure. Check the steam vent and pressure regulator for blockages. Finally, ensure sufficient liquid is inside the cooker, as adequate moisture is crucial for proper sealing.

Pressure Regulator Problems

If experiencing issues with the pressure regulator, first ensure it’s clean and free from food particles. A clogged regulator can prevent proper pressure control or cause erratic venting. Inspect the valve for any damage or wear, replacing it if necessary.

Confirm the correct weight or setting is selected for your desired pressure level. Excessive steam or failure to reach pressure indicates a potential regulator malfunction. Always refer to the manual for specific regulator troubleshooting steps.

Food Burning

Food burning often results from insufficient liquid in the pot or cooking at too high a temperature. Always ensure adequate liquid levels are met, as specified in your recipe. Reduce the heat setting if scorching occurs during cooking.

Stirring food occasionally can prevent sticking and burning, especially with thicker sauces or stews. Check the sealing ring for proper placement and condition, as a faulty seal can affect temperature regulation. Refer to recipes for appropriate cooking times.

Fagor Pressure Cooker Models: A Brief Overview

Fagor offers diverse models like the Duo, Premium, and Rapida, each with unique features. Explore specific model manuals for detailed operation instructions.

Fagor Duo Pressure Cooker

The Fagor Duo is a versatile model appreciated for its multi-functionality, offering pressure cooking, slow cooking, and browning capabilities. Users on forums have noted that the included operating instructions can be somewhat lacking in detail, requiring supplemental research.

Ensure you thoroughly read the safety instructions before first use. Proper lid sealing is crucial, and the manual details how to achieve this. Refer to the Fagor America website for downloadable manuals and additional support resources to maximize your cooking experience.

Fagor Premium Pressure Cooker

The Fagor Premium model emphasizes ease of use and advanced features. Before operation, carefully remove all packing materials, including those within the removable cooking pot. Crucially, the manual stresses the importance of reading all safety instructions prior to plugging in the unit.

Users should familiarize themselves with the pressure release mechanisms detailed in the manual. Fagor America provides comprehensive resources, and online communities offer troubleshooting advice for common issues like lid sealing.

Fagor Rapida Pressure Cooker

The Fagor Rapida is designed for quick and efficient cooking. The user manual highlights the necessity of thoroughly reading the safety instructions before initial use. Removing all packaging materials, both inside and outside the cooker, is a crucial first step.

Fagor America’s website offers additional support, while forums like Miss Vickies provide user feedback on operating instructions. Understanding the pressure release methods detailed in the manual is vital for safe operation.

Recipes and Cooking Times

Explore diverse recipes – rice, meats, and vegetables – with optimized cooking times for your Fagor pressure cooker, ensuring delicious and efficient meals.

Basic Rice Cooking

Achieving perfectly cooked rice in your Fagor pressure cooker is remarkably simple. Begin by rinsing one cup of rice under cold water until the water runs clear. Add the rinsed rice and 1.5 cups of water to the cooking pot.

Secure the lid, select the appropriate pressure level (typically low to medium), and cook for approximately 5-7 minutes.

Allow for natural pressure release for 10 minutes, then carefully release any remaining pressure. Fluff with a fork before serving – enjoy fluffy, delicious rice every time!

Meat and Poultry Recipes

Fagor pressure cookers excel at tenderizing tougher cuts of meat and poultry; For pot roast, sear the meat first, then add vegetables, broth, and seasonings. Cook on high pressure for 30-45 minutes, followed by natural pressure release.

Chicken breasts require less time – approximately 8-12 minutes on high pressure, with quick release.

Always ensure meat reaches a safe internal temperature. Experiment with marinades and spices for flavorful results; your Fagor cooker delivers consistently moist and delicious meals.

Vegetable and Bean Recipes

Fagor pressure cookers are ideal for quickly cooking vegetables and beans, preserving their nutrients and vibrant colors. Dried beans, like chickpeas or kidney beans, require no pre-soaking – cook for 25-30 minutes on high pressure, followed by natural release.

For tender-crisp vegetables, such as broccoli or green beans, use 3-5 minutes on high pressure with a quick release.

Experiment with herbs and spices to enhance flavors; your Fagor cooker simplifies healthy and delicious vegetable-based meals.

Understanding Pressure Cooking Benefits

Fagor pressure cookers offer faster cooking, retaining more nutrients, and improving energy efficiency. Enjoy flavorful meals in less time with reduced energy consumption!

Faster Cooking Times

Fagor pressure cookers significantly reduce cooking durations compared to conventional methods. This is achieved by creating a sealed environment, increasing internal pressure, and raising the boiling point of liquids.

Foods that typically require hours, like tough cuts of meat or dried beans, can be ready in a fraction of the time. This benefit is invaluable for busy individuals and families seeking convenient meal preparation without compromising on taste or quality.

Enjoy delicious, home-cooked meals even on hectic weeknights thanks to the speed and efficiency of your Fagor appliance.

Nutrient Retention

Pressure cooking with your Fagor appliance excels at preserving vital nutrients often lost during traditional cooking. The sealed environment minimizes oxidation and leaching of vitamins and minerals into cooking water.

Reduced cooking times also contribute to better nutrient retention, as prolonged heat exposure degrades sensitive compounds.

Enjoy healthier, more nutritious meals knowing that your Fagor pressure cooker helps retain the goodness of your ingredients, providing maximum health benefits for you and your family.

Energy Efficiency

Utilizing your Fagor pressure cooker significantly reduces energy consumption compared to conventional cooking methods. The sealed pot traps steam, creating a more efficient heating environment and drastically shortening cooking times.

Less energy is required to reach and maintain cooking temperatures, lowering your electricity or gas bills.

Embrace sustainable cooking with Fagor, minimizing your carbon footprint while enjoying delicious, quickly prepared meals. It’s a win-win for both your wallet and the environment!

Where to Find Additional Resources

Explore the Fagor America website for manuals and support. Online forums, like Miss Vickies, offer user tips and troubleshooting assistance.

Fagor America Website

The official Fagor America website serves as a primary hub for comprehensive support regarding your pressure cooker. Here, you can typically locate downloadable versions of your specific model’s manual, ensuring you always have access to crucial operating instructions and safety guidelines.

Furthermore, the website often features frequently asked questions (FAQs) addressing common user concerns, alongside potential troubleshooting steps for resolving minor issues. Direct access to customer service contact information is also readily available, allowing you to connect with Fagor representatives for personalized assistance when needed.

Online Forums and Communities

Numerous online forums and communities, such as the Miss Vickies Pressure Cooker Forum, offer valuable insights and shared experiences from fellow Fagor pressure cooker users. These platforms provide a space to ask questions, discuss troubleshooting tips, and exchange recipes tailored to your appliance.

Often, users share solutions to common problems not explicitly covered in the official manual, offering practical advice and workarounds. Engaging with these communities can significantly enhance your understanding and enjoyment of your Fagor pressure cooker.

Manual Download Locations

Locating your Fagor pressure cooker manual is straightforward through several online resources. The Internet Archive hosts digitized versions, offering free download and streaming access to various models. Fagor America’s website is the primary source for official manuals, ensuring you have the most up-to-date information.

Manualzilla also provides a collection of appliance manuals, including Fagor models. Searching these platforms using your specific model number will yield the correct documentation for optimal use and safety.

Warranty Information

Fagor provides coverage details for its pressure cookers, outlining the claim process for defects. Review your purchase documentation for specific terms and conditions.

Coverage Details

Fagor’s warranty typically covers defects in materials and workmanship under normal household use. The duration varies by model, often ranging from one to two years from the original purchase date. This warranty doesn’t cover damage resulting from misuse, accidents, unauthorized repairs, or normal wear and tear.

Specifically, it generally excludes issues caused by improper cleaning, failure to follow operating instructions, or using the cooker for commercial purposes. Always retain proof of purchase for warranty claims.

Claim Process

To initiate a warranty claim, contact Fagor America’s customer service department with your model number, serial number, and proof of purchase. You may be required to provide photos or videos demonstrating the defect. Fagor will then assess the claim and, if approved, offer repair or replacement.

Shipping costs for returning the defective unit may be the responsibility of the customer. Fagor reserves the right to inspect the product to verify the warranty claim’s validity.